AUTOMOTIVE

Tips and Tricks for Perfect Radiator Repair

Let me tell you about the time I first discovered my passion for radiator repair Dubai – it wasn’t exactly a planned career move. Picture this: I’m stranded on the side of Interstate 95, steam billowing from under my hood like a locomotive, and my phone showing “no service.” That day changed everything. Twenty years later, here I am, sharing what I’ve learned through countless repairs, burned fingers, and those satisfying moments when an engine finally runs at the perfect temperature. Your car’s radiator isn’t just another part under the hood; it’s the heart of your cooling system, and like any heart, it needs proper care to keep everything running smoothly.

Spotting Trouble Before It Spots You

You know that sinking feeling when your temperature gauge starts creeping into the red? I’ve been there more times than I can count, both with my own vehicles and helping others. Just last month, Mrs. Johnson from down the street pulled into my driveway with her minivan, making sounds that would scare a mechanic. The sweet, syrupy smell of coolant filled the air – a smell that instantly took me back to my first radiator repair job. These days, I can almost diagnose a radiator problem with my eyes closed. From the telltale puddles of green or orange liquid under your car to that unmistakable overheating issue during your morning commute, these warning signs are your radiator’s way of crying for help.

Getting Your Hands Dirty: The Right Tools Make the Difference

Boy, do I wish someone had told me about proper tools when I started! I remember trying to fix a leak with my dad’s old wrench set and a prayer. These days, my garage looks like a mini radiator repair shop, but you don’t need everything I’ve collected over two decades. Start with the basics: a reliable pressure tester (saved my pennies more times than I can count), a good set of screwdrivers (both flathead and Phillips), some sturdy pliers, and wrenches that actually fit your car’s specifications. Don’t forget safety gear – my left arm still has a scar from learning that lesson the hard way. The hot coolant is no joke, folks.

The Detective Work: Finding Those Sneaky Leaks

Finding a radiator leak is like solving a mystery, and I’ve become quite the detective over the years. There was this one time, working on my neighbor’s truck, when the leak was so tiny it took me three hours to find it. Had to wait until dusk and use a flashlight to catch the reflection of the coolant in just the right light. Start your investigation when the engine’s cold – trust me on this one. My technique? Mix up your coolant solution, pressurize the system (not too much, mind you), and watch like a hawk. Those tricky leaks love to hide around seams and corners, especially on those older models from the ’90s.

Rolling Up Your Sleeves: The Actual Repair Work

Here’s where the rubber meets the road, as we say in the business. Every radiator tells a different story, and each repair needs its own approach. Take this Chevy I worked on last week – a perfect example of why you can’t just slap some sealant on everything and call it a day. The owner had already tried three different “quick fixes” from the auto parts store, making the real repair twice as complicated. For plastic radiators (which seem to be everywhere these days), you need a steady hand and the right welding technique. Metal radiators? Well, that’s a whole different ballgame, requiring either soldering or brazing, depending on the damage.

Keeping Things Running Smooth: Maintenance Matters

If I had a dollar for every time someone said, “I didn’t know I needed to maintain my radiator,” I could retire tomorrow. Listen, your cooling system is like a complex ecosystem – everything needs to work together just right. I check my own vehicles’ coolant levels every month without fail, and you should, too. Learned this habit after rebuilding one too many engines that were cooked from neglect. A complete flush every two years might seem excessive to some, but I’ve seen what builds up in there. Those deposits can turn your radiator into a clogged mess faster than you’d believe.

When to Wave the White Flag and Call for Help

Look, I’m the first guy to encourage people to learn about their vehicles, but sometimes you need to know when to step back. Had a young fellow bring in his prized Mustang last summer – he’d tried fixing a cracked radiator core himself and ended up making things much worse. Modern cooling systems are getting more complex by the year, with all sorts of sensors and computer-controlled components that weren’t around when I started. Sometimes, paying a professional is cheaper than learning from your mistakes.

The Long Game: Smart Investments in Your Cooling System

Through all my years working on radiators, one thing’s become crystal clear – cutting corners always costs more in the end. I keep a logbook for every vehicle I work on, something my old mentor taught me. Write down everything: repairs, maintenance, even small adjustments. It’s like having a medical history for your car. And please, for the love of all things mechanical, don’t buy the cheapest coolant you can find. That’s like putting discount oil in a Ferrari – sure, it might work, but for how long?

Looking back at all these years of radiator repairs, each job has taught me something new. Every engine and every cooling system has its quirks and personalities. That’s what keeps this work interesting – no two days are exactly alike. Keep these tips in mind: treat your radiator with respect, and it’ll keep your engine purring for years to come. And if you ever find yourself stuck with steam coming from under your hood, well, now you know what to do. At German Experts, we follow the same philosophy when it comes to vehicle maintenance – never compromise on quality

AUTOMOTIVE

Getting Started with MataRecycler: Tips and Best Practices

Introduction to MataRecycler

Welcome to the world of MataRecycler, where recycling becomes not just a responsibility but an empowering journey. As environmental concerns grow, every small action counts. MataRecycler is here to simplify your role in creating a cleaner planet. Whether you’re new to recycling or looking for ways to enhance your efforts, this guide will equip you with essential tips and best practices. Dive into the exciting realm of sustainable living and discover how easy it can be to make a difference!

Benefits of Using MataRecycler

MataRecycler offers numerous benefits that make recycling easier and more efficient. One standout advantage is its user-friendly interface, designed to simplify the recycling process for everyone.

With MataRecycler, you can easily track your recycling habits. This feature encourages responsible behavior and helps users understand their impact on the environment.

Another benefit is community engagement. Many users share tips and success stories, fostering a sense of teamwork in achieving sustainability goals.

The platform also provides educational resources about local recycling regulations. Staying informed ensures you’re not just throwing items in the bin but actively contributing to your community’s environmental efforts.

Additionally, using MataRecycler often leads to reduced waste overall. By encouraging mindful consumption, it promotes an eco-friendly lifestyle that resonates beyond individual actions.

Understanding the Recycling Process

The recycling process is a fascinating journey that transforms waste into valuable resources. It begins the moment you sort your recyclables at home.

Once collected, materials are transported to recycling facilities. Here, they undergo thorough inspection and sorting. Workers or machines separate items based on material type—plastic, glass, paper, and metal.

Next comes cleaning. Contaminants like food residues can ruin batches of recyclable materials. So it’s crucial to rinse containers before tossing them in the bin.

After cleaning, the materials are shredded or crushed into smaller pieces for easier processing. They’re then melted down or pulped depending on their nature.

These raw materials are turned back into new products. This cycle not only conserves natural resources but also reduces landfill waste and pollution associated with manufacturing processes.

Tips for Properly Sorting and Preparing Recyclables

Sorting recyclables correctly is crucial for effective recycling. Start by familiarizing yourself with local guidelines. Different regions may have specific rules about what can and cannot be recycled.

Rinse containers before recycling. Leftover food or liquids can contaminate materials, making them unsuitable for processing. A quick rinse goes a long way in ensuring your items are clean.

Flatten cardboard boxes to save space and facilitate easier handling at recycling facilities. This small step helps the entire process run more smoothly.

Keep plastic bags out of your curbside bin; they often jam machinery at recycling centers. Instead, take them to designated drop-off locations or reuse them when possible.

Avoid wishcycling—placing non-recyclable items into bins hoping they’ll be accepted. Always check labels and educate yourself on what belongs in the recycle bin to enhance overall efficiency.

Best Practices for Maximizing Recycling Efforts

To maximize your recycling efforts with MataRecycler, start by staying informed about the materials accepted in your local program. Each area may have specific guidelines, so check regularly.

Creating a designated space for recyclables at home can streamline the process. Use clearly labeled bins to prevent contamination and ensure everything is sorted correctly.

Engage your family or housemates in the effort. Making recycling a shared responsibility fosters awareness and commitment among everyone involved.

Consider rinsing containers before placing them in the bin. This simple step reduces odors and keeps pests away while ensuring that items are clean enough for processing.

Stay updated on community events related to recycling or waste reduction. Participating in workshops or local cleanup days can enhance knowledge and inspire others to join you on this journey toward sustainability.

Common Mistakes to Avoid When Recycling with MataRecycler

Many people think all plastics are recyclable, but that’s not always true. Check for recycling symbols and follow local guidelines to avoid contamination.

Another mistake is failing to clean your recyclables. Residual food or liquids can spoil an entire batch of materials. Rinsing containers before tossing them into the bin makes a significant difference.

Mixing different types of recyclables can also be problematic. Keep paper separate from glass and metals to streamline processing at facilities.

Don’t forget about items that might seem harmless, like plastic bags or pizza boxes—they often can’t be recycled through regular programs. Always verify what’s accepted in your area.

Procrastination can lead to overflow bins or improper disposal methods. Set a schedule for recycling sessions to stay organized and responsible with your waste management efforts.

Conclusion: Join the Movement and Make a Positive Impact on the Environment

The journey with MataRecycler is more than just a task; it’s an opportunity to make a lasting difference. By adopting proper recycling habits, you contribute to a cleaner planet and inspire others in your community. Embrace the tips shared here, engage with the recycling process actively, and share knowledge about best practices.

Every small effort counts when it comes to sustainability. As you sort through your recyclables and avoid common pitfalls, remember that this collective action propels us toward a greener future. Join the movement today—your actions matter immensely in safeguarding our environment for generations to come. Together, we can create significant change by simply choosing to recycle wisely with MataRecycler.

AUTOMOTIVE

Compacted Graphite: Revolutionizing the Automotive Industry

Introduction to Compacted Graphite

The automotive industry is constantly evolving, driven by the quest for better performance, efficiency, and sustainability. Among the numerous innovations that have emerged over the years, one material stands out: compacted graphite. This unique form of graphite has garnered attention for its remarkable properties and applications in vehicle manufacturing. As cars become more complex and demanding in terms of durability and weight reduction, compacted graphite offers a promising solution that could change the game entirely.

Imagine a lightweight yet incredibly strong material capable of withstanding extreme temperatures and pressures. Compacted graphite not only meets these requirements but also presents opportunities to enhance fuel efficiency while lowering emissions. With car manufacturers exploring every avenue to meet stringent environmental standards, this revolutionary material might just be what they’re looking for to push their designs forward.

Join us as we delve into the fascinating world of compacted graphite—its history, advantages, applications across various car parts, benefits for both manufacturers and consumers alike—all while uncovering potential challenges it faces in adoption within the industry.

History and Development of Compacted Graphite

Compacted graphite has a fascinating history that dates back to the early 20th century. Initially discovered in cast iron, engineers and researchers began exploring its unique properties.

The breakthrough came when scientists recognized compacted graphite’s potential for strength and thermal conductivity. This material exhibits characteristics between traditional gray iron and ductile iron, offering an intriguing blend of benefits.

Throughout the decades, advancements in manufacturing techniques enabled more efficient production processes. Innovations such as controlled cooling methods refined the structure of compacted graphite, enhancing its performance significantly.

In recent years, demand surged within various industries, particularly automotive manufacturing. As car makers seek lighter materials without compromising durability, compacted graphite emerged as a game-changer.

Continuous research is ongoing to further optimize this remarkable material for diverse applications across engineering fields. The journey of compacted graphite demonstrates how innovation can reshape industry standards while addressing modern challenges.

Advantages of Using Compacted Graphite in the Automotive Industry

Compacted graphite offers remarkable benefits that are transforming the automotive landscape. Its high strength-to-weight ratio allows manufacturers to create lighter vehicles without sacrificing durability.

This material excels in thermal conductivity, enhancing engine efficiency. As a result, engines can run cooler and more effectively, improving performance while reducing emissions.

Additionally, compacted graphite boasts superior wear resistance compared to traditional materials. This longevity translates into reduced maintenance costs for both manufacturers and consumers alike.

The ability to mold compacted graphite into various shapes opens doors for innovative designs. Engineers can push boundaries with parts that were previously challenging or impossible to produce using conventional materials.

Moreover, compacted graphite is sustainable. It encourages eco-friendly practices by enabling the creation of fuel-efficient vehicles that align with modern environmental standards. This shift not only benefits carmakers but also resonates well with environmentally conscious consumers seeking greener options in their vehicle choices.

Applications of Compacted Graphite in Different Car Parts

Compacted graphite is making waves in various automotive components. Its unique properties lend themselves well to high-stress environments.

Engine blocks are a prime example. The material’s strength and durability enhance performance while reducing weight, improving fuel efficiency overall.

Another application lies within cylinder heads. Compacted graphite can withstand extreme temperatures and pressures, providing reliable sealing and longevity for the engine’s lifespan.

Even brake systems benefit from this innovative material. Its excellent thermal conductivity helps dissipate heat effectively, enhancing braking performance under demanding conditions.

Suspension parts also utilize compacted graphite due to its resistance to wear and cracking. This contributes to better handling and stability during drives.

Manufacturers are excited about integrating compacted graphite into exhaust systems too. It resists corrosion while maintaining structural integrity, which is crucial for long-term use in harsh environments.

Benefits for Car Manufacturers and Consumers

Compacted graphite offers numerous advantages for car manufacturers and consumers alike. For automakers, the material’s lightweight nature translates into improved fuel efficiency. This is increasingly important as global emissions regulations tighten.

Additionally, compacted graphite boasts excellent thermal conductivity. This helps in managing engine temperatures more effectively. It reduces the risk of overheating while enhancing overall performance.

For consumers, vehicles made with compacted graphite typically provide better longevity. Components such as cylinder heads and engine blocks experience less wear and tear compared to traditional materials.

Moreover, the improved strength-to-weight ratio means cars can perform at higher levels without sacrificing safety or comfort. Drivers appreciate a smooth driving experience that doesn’t compromise on power or efficiency.

In an age where sustainability matters, this material’s potential for reducing environmental footprints resonates well with eco-conscious buyers looking for greener alternatives in their automotive choices.

Challenges and Limitations of Using Compacted Graphite

Compacted graphite presents several challenges that manufacturers must navigate. One of the primary concerns is its cost. Producing compacted graphite requires specialized techniques, which can elevate expenses compared to conventional materials.

Another limitation lies in machining capabilities. While compacted graphite has superior properties, it can be more difficult to work with during manufacturing processes. This could extend production times and complicate design modifications.

Additionally, the material’s thermal expansion characteristics need careful consideration. Variations in temperature may lead to dimensional changes that affect performance if not properly managed.

Moreover, while compacted graphite offers impressive strength, it isn’t impervious to brittleness under certain conditions. Engineers must analyze specific applications thoroughly to ensure reliability over time.

Widespread adoption hinges on overcoming industry resistance to change. Many companies are hesitant to invest in new technologies without proven long-term benefits.

Future Possibilities and Innovations in the Use of Compacted Graphite

The future of compacted graphite in the automotive sector is bright and full of potential. As technology advances, researchers are exploring new methods to enhance its properties further.

Innovations could lead to lighter materials without sacrificing strength. This would significantly improve fuel efficiency and reduce emissions in vehicles.

Additionally, integrating smart technologies into compacted graphite components may offer exciting possibilities. Imagine sensors embedded within engine parts that monitor performance in real-time.

Another intriguing avenue involves 3D printing with compacted graphite composites. This method could revolutionize manufacturing processes, allowing for customized designs tailored to specific vehicle needs.

As the push for sustainable practices grows, compacted graphite’s recyclability may also play a crucial role. Future developments might focus on creating eco-friendly alternatives or repurposing used materials effectively.

With ongoing research and creativity, the automotive industry stands on the cusp of transforming how we view this versatile material.

Conclusion

Compacted graphite is transforming the automotive landscape. This innovative material combines the best properties of cast iron and steel, offering strength without compromising on weight. As manufacturers continue to explore its potential, we can anticipate exciting advancements in vehicle performance and efficiency.

The ongoing research into compacted graphite also opens doors for new applications beyond traditional automotive uses. Its versatility may lead to developments in other industries, enhancing manufacturing processes worldwide.

Car manufacturers are likely to benefit from reduced production costs while delivering a superior product to consumers. As compacted graphite gains traction, it promises a future where vehicles are more fuel-efficient and environmentally friendly.

With each passing year, the technology surrounding compacted graphite evolves. The focus remains on overcoming challenges associated with scalability and cost-effectiveness while maximizing its benefits. The journey of this remarkable material has only just begun, hinting at limitless possibilities ahead for both car makers and drivers alike.

AUTOMOTIVE

Understanding CVT Transmission: The Future of Smooth Driving

Have you ever wondered what makes certain cars feel like they glide over the road, offering an incredibly smooth driving experience? The secret often lies in a technology known as CVT transmission. This innovative system is revolutionizing how we think about vehicle performance and efficiency. As more manufacturers adopt this engineering marvel, understanding its mechanics and benefits becomes essential for every car enthusiast or potential buyer.

In this article, we’ll delve into the world of CVT transmission—what it is, how it works, and why it’s capturing the attention of both drivers and automakers alike. From its advantages to some drawbacks worth considering, let’s explore what makes CVT a game-changer on today’s roads.

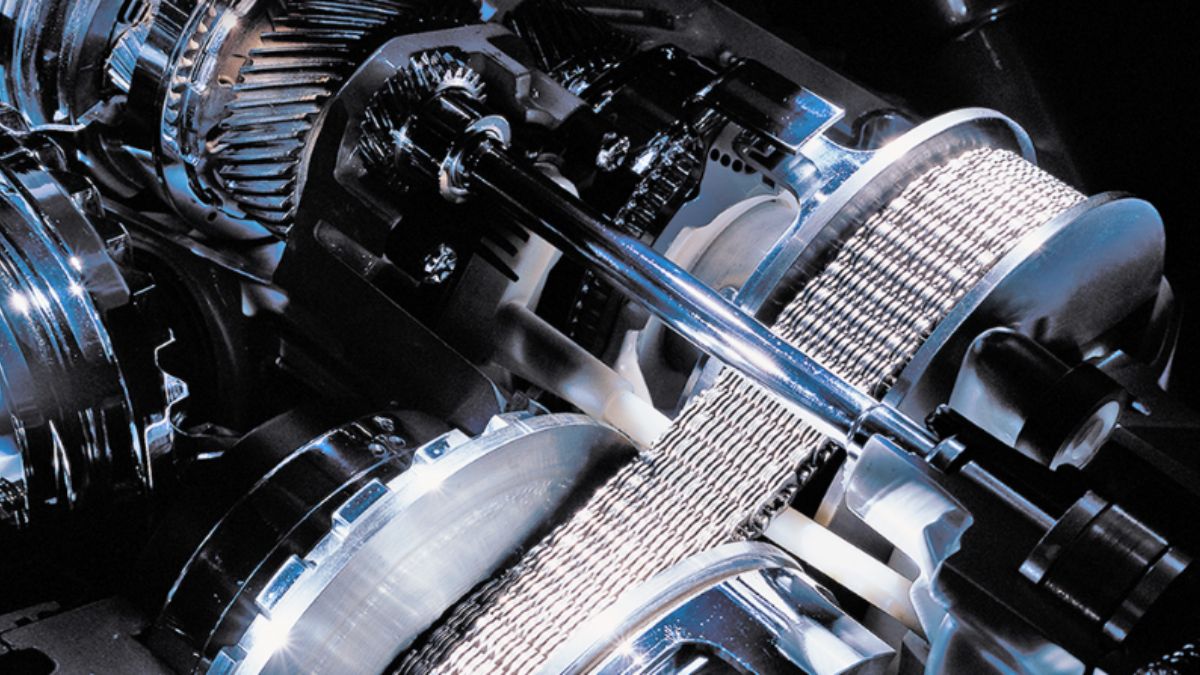

What is a CVT Transmission?

CVT stands for Continuously Variable Transmission. Unlike traditional automatic transmissions, which use a fixed number of gears, CVTs offer a seamless range of gear ratios. This means that rather than shifting from one gear to another, the system can adjust itself continuously.

At its core, a CVT utilizes two pulleys connected by a belt or chain. As the vehicle accelerates or decelerates, these pulleys change their diameter automatically. This allows for an infinite variety of effective gear ratios and helps maintain optimal engine performance at various speeds.

The result is smooth acceleration without the noticeable shifts found in conventional systems. Drivers often appreciate this fluidity during everyday driving conditions. Furthermore, it’s designed to enhance fuel efficiency by keeping the engine running at its most efficient RPMs regardless of speed changes on the road.

The Advantages of CVT Transmission

CVT transmissions offer a unique driving experience that many enthusiasts appreciate. One of the standout advantages is their ability to provide seamless acceleration. Unlike traditional gear systems, CVTs adjust continuously to deliver power without noticeable shifts.

Fuel efficiency is another significant perk. By keeping the engine in its optimal RPM range, these transmissions can help drivers save at the pump. Many manufacturers tout impressive mileage figures attributed to CVT technology.

Another benefit lies in smoothness during operation. Drivers enjoy a quieter ride with less vibration and noise compared to conventional automatics. This enhances comfort on long journeys.

Additionally, CVTs often feature lighter components than traditional transmission systems. This reduction in weight contributes positively to overall vehicle performance and handling.

With fewer moving parts, maintenance can be simplified as well. A well-maintained CVT can lead to lower long-term ownership costs due to reduced wear and tear over time.

The Disadvantages of CVT Transmission

While CVT transmissions offer smooth driving experiences, they come with some drawbacks. One notable issue is the lack of a traditional “feel” when accelerating. Some drivers miss the distinct shifts found in automatic or manual transmissions.

Another concern is durability. Although advancements have improved their reliability, CVTs can experience wear and tear more quickly than other transmission types under heavy loads or aggressive driving conditions.

Additionally, repair costs for CVTs tend to be higher. If something goes wrong, finding qualified mechanics who specialize in this technology can be a challenge.

Noise can also be an issue. Many users report that CVTs create more engine noise during acceleration compared to conventional systems, which might detract from the overall driving experience.

Not all vehicles are equipped with a CVT option yet. This limits choice for consumers who prefer this innovative transmission system over traditional methods.

Differences between CVT and Traditional Automatic Transmissions

CVT, or continuously variable transmission, operates quite differently from traditional automatic transmissions. While a conventional automatic uses fixed gears to shift through different speeds, a CVT offers an infinite range of gear ratios. This unique design allows for seamless acceleration without the noticeable shifts.

In terms of driving experience, CVTs provide smoother performance and better fuel efficiency. Traditional automatics can often exhibit a jarring sensation during gear changes, which is absent in CVTs.

However, they also come with their own characteristics. For instance, many drivers notice that a CVT can feel less engaging due to its lack of defined shifting points. In contrast, traditional automatics deliver distinct shifts that some enthusiasts prefer.

Maintenance varies as well; while both systems require care, CVTs might need specialized attention due to their complex nature and unique components.

Maintenance and Care for CVT Transmissions

Maintaining a CVT transmission is key to ensuring its longevity and performance. Regular fluid changes are essential, as the transmission relies on clean fluid for optimal function. Check your owner’s manual for recommended intervals.

Monitoring the fluid level is also crucial. Low levels can lead to overheating and eventual failure. Always use the manufacturer-approved CVT fluid when topping off or replacing it.

Listen for unusual noises while driving, such as whining or slipping sensations. These could signal underlying issues that need immediate attention.

Avoid aggressive driving habits like rapid acceleration or hard braking. Gentle driving promotes smoother operation and reduces wear on the CVT system over time.

The Future of CVT Transmission in the Automotive Industry

The future of CVT transmission is bright and promising. As automakers increasingly focus on fuel efficiency, the advantages of this technology are becoming more apparent.

With advancements in engineering, we can expect even smoother transitions between gear ratios. This enhancement will lead to a more enjoyable driving experience. Manufacturers are investing heavily in research and design to improve durability as well.

Electric vehicles (EVs) also play a role in shaping the future landscape of CVTs. Many EVs utilize similar principles for their power delivery systems, making the transition to electric propulsion seamless.

We may see hybrid models that combine traditional engines with CVT systems, optimizing both performance and efficiency. The automotive industry is evolving rapidly, and CVT transmissions are poised to be at the forefront of these changes.

Conclusion

Continuously Variable Transmission, commonly known as CVT transmission, represents a significant departure from traditional automatic gearboxes. Unlike conventional transmissions that rely on fixed gears to shift through speeds, the CVT utilizes a system of pulleys and belts that allows for seamless acceleration. This innovative design provides an infinite number of effective gear ratios, optimizing engine performance while enhancing fuel efficiency.

CVTs come with numerous advantages. They offer smoother acceleration without the noticeable shifts felt in traditional automatics. Drivers enjoy a more fluid driving experience, particularly during stop-and-go traffic or highway merging scenarios. Additionally, because the engine can operate at its most efficient RPM range consistently, fuel efficiency often sees substantial improvement compared to regular transmissions. Many find that this translates into fewer trips to the gas station and overall cost savings over time.

Another perk is reduced mechanical wear due to fewer moving parts involved in shifting gears. This feature enhances durability and longevity when properly maintained.

Despite their benefits, there are some drawbacks associated with CVTs worth considering. One common criticism is their unique driving feel; some drivers may find themselves missing the tactile feedback provided by conventional systems during gear changes.

Moreover, repair costs can be higher if issues arise since specialized knowledge and components are often required for maintenance and fixes. Some car enthusiasts also express concerns about performance under high-stress conditions such as towing heavy loads or aggressive driving styles where traditional transmissions might excel.

When comparing cvt transmission to traditional automatic options like torque converters or dual-clutch systems, it’s clear that each has distinct characteristics catering to different driver preferences. Traditional automatics typically engage specific gears leading to pronounced shifts creating an engaging experience for many drivers who appreciate feeling every change in speed.

Conversely, cvt technology eliminates these discrete shifts altogether resulting in uninterrupted power delivery but potentially sacrificing some sensory

-

TECHNOLOGY8 months ago

TECHNOLOGY8 months agoTop 10 Must-Read Stories from Kristen Archives You Can’t Miss

-

TECHNOLOGY1 year ago

TECHNOLOGY1 year agoSky Bri Net Worth Revealed: How She Built Her Financial Empire

-

TOPIC1 year ago

TOPIC1 year agoBasement Renovation Contractors: How They Tackle Structural Issues During Renovations

-

TOPIC10 months ago

TOPIC10 months ago5 Reasons the //Vital-Mag.Net Blog Dominates Lifestyle

-

BEAUTY1 year ago

BEAUTY1 year agoRevitalize Your Hair with Oribe Hair Care for Damaged Hair: Style It with Blue Dresses for Weddings and Events

-

TOPIC9 months ago

TOPIC9 months agoTop 10 Articles from the ://Vital-Mag.net Blog That You Can’t Miss

-

CRYPTO1 year ago

CRYPTO1 year agoCrypto30x.com Review: Is It the Right Platform for You?

-

BUSINESS8 months ago

BUSINESS8 months agoTraceLoans Explained What You Need to Know